--> Adds Singapore Electric Vehicle Center of Excellence to its network in the region, covering every segment in the electric vehicles supply chain

--> Customized solutions in more than 10 countries across Asia Pacific

--> Safety and compliance at the core of solution design to cater to rising demand as Asia drives the electric vehicles sector forward

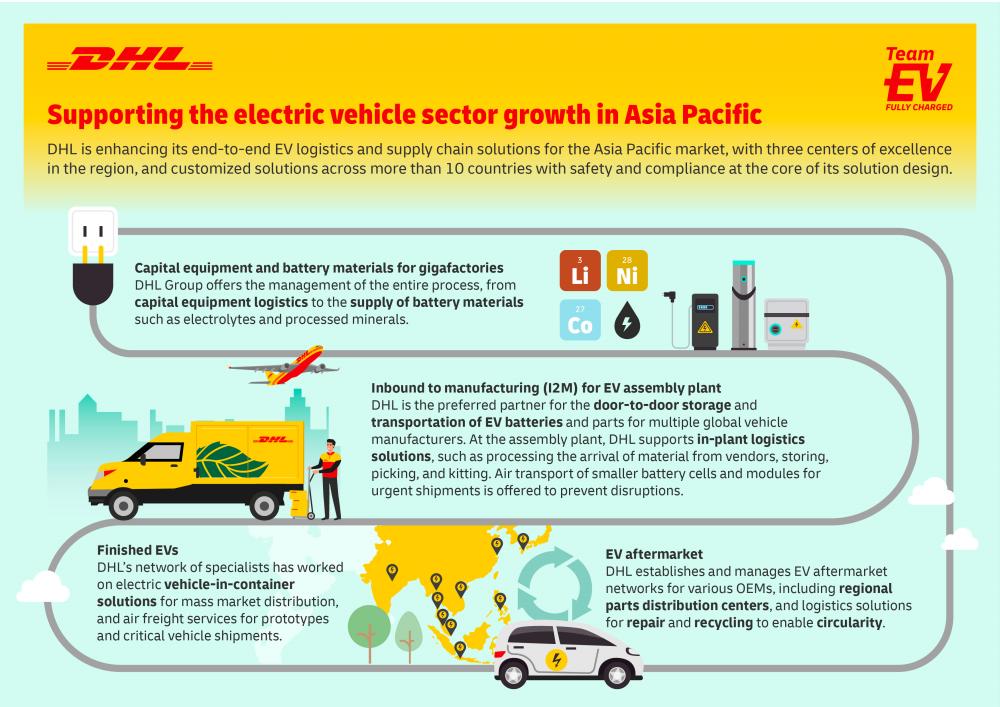

SINGAPORE - Media OutReach Newswire - 3 March 2025 - DHL Group (DHL), the world’s leading logistics company, is enhancing its end-to-end EV logistics and supply chain solutions for the Asia Pacific market, with the opening of three Electric Vehicle (EV) Centers of Excellence (COEs) within the region in 2024. These COEs build on DHL’s offering of customized solutions covering capital equipment for new EV-related factories, inbound-to-manufacturing (I2M), finished vehicles and aftermarket logistics in the region.

“Over the next five years, Asia is expected to account for 63% of the new 115 million EVs sold worldwide.[1] A robust and compliant logistics supply chain ecosystem is needed to support this growing demand, and our EV Centers of Excellence in Shanghai, Singapore, and Indonesia serve as hubs of competencies and resources for the growing EV industry across the Asia Pacific , “ said Fathi Tlatli, Global Auto-Mobility Sector President, DHL Customer Solutions and Innovation.

EV COEs to provide a network of expertise in Asia

An EV COE is a center of knowledge and know-how, showcasing existing EV logistics expertise, capability, and resources and demonstrating DHL Group’s commitment to further enhance its EV offerings. These centers cover a wide range of solutions, offering modular and integrated end-to-end logistics across the EV supply chain.

The three EV COEs in China, Singapore and Indonesia are connected to a global network of COEs in 10 countries including Italy, United Kingdom, Mexico and the United Arab of Emirates.

“When people think of EVs, it is often associated with the finished vehicle itself. However, there is an entire complex ecosystem behind the EV value chain, which is crucial in orchestrating the process. That is our advantage as DHL Group, as we can offer customized solutions for every segment utilizing our expertise and our extensive global network,“ said Audrey Gerard, Vice President of Auto-Mobility, Asia Pacific, DHL Customer Solutions and Innovation.

EV COEs will also be established in other countries with an existing EV footprint and expertise, such as India, Japan, Malaysia and Thailand.

DHL Group will continue focusing on the EV sector, with the New Energy sector identified as a key growth area in its Strategy 2030. As the sector matures, there is an increasing need to repurpose end-of-life EV parts and batteries or recycle them for raw materials.

“This segment will require complex logistics support, which we are exploring in the region leveraging solutions implemented in Europe and the Middle East networks as well as a market-leading cross-border road freight network in the ASEAN region,“ said Tlatli.

Customized EV Solutions on showcase at the new EV COEs

Capital equipment and battery materials for gigafactories

For companies expanding their mining of EV battery minerals and battery manufacturing operations globally, DHL Group offers the management of the entire process, from capital equipment logistics to the supply of battery materials such as electrolytes and processed minerals.

Inbound to manufacturing (I2M) for EV assembly plant

Today, DHL is the preferred partner for the door-to-door storage and transportation of EV batteries and parts for multiple global vehicle manufacturers. Control towers oversee these solutions, managing the suppliers and tracking end-to-end temperature, humidity, and geolocalization data to ensure safety and performance. At the assembly plant, DHL supports in-plant logistics solutions, such as processing the arrival of material from vendors, storing, picking, and kitting. Air transport of smaller battery cells, modules, and critical components for urgent shipments is offered to prevent disruptions.

Finished EVs

DHL’s network of specialists has worked on electric vehicle-in-container solutions for mass market distribution, and air freight services for prototypes and critical vehicle shipments. Across 2024, DHL delivered soon-to-be-launched vehicle prototypes from China to Europe, including customized boxes, dangerous goods (DG) checks, and the management of export clearance.

At the destination, additional finished vehicle services for pre-delivery inspection and yard management have been implemented in several geographies.

EV aftermarket

DHL establishes and manages EV aftermarket networks for various Western and Asian OEMs, including regional and local part distribution centers in key Asia Pacific markets, such as India, Indonesia, Japan, Malaysia, the Philippines, Singapore, Thailand, and Vietnam. It has developed EV parts and battery-specific solutions, such as shared storage facilities, to cover requirements from compliance, import, storage, and time-definite deliveries to dealerships.